The Weekly Reflektion 39/2023

Starting up a facility after a maintenance shutdown is a critical phase and needs the full attention of the operations team. Equipment has been opened, flanges disturbed, modifications carried out, safety systems maintained and hopefully re-instated correctly etc. There is a high level of uncertainty on the integrity of the facility and the risk is high. Mitigation measures need to be in place to manage this risk.

How do you ensure a safe start-up of your facility?

In last week’s Reflektion, week 38/2023 we covered a fire at the Kuraray ethylene and vinyl alcohol copolymer (EVAL) plant in Pasedena on 19th May 2018. This week we will look at why the incident occurred and delve into the technical details that led to the release of 1000 kgs of ethylene into an area where construction work was ongoing.

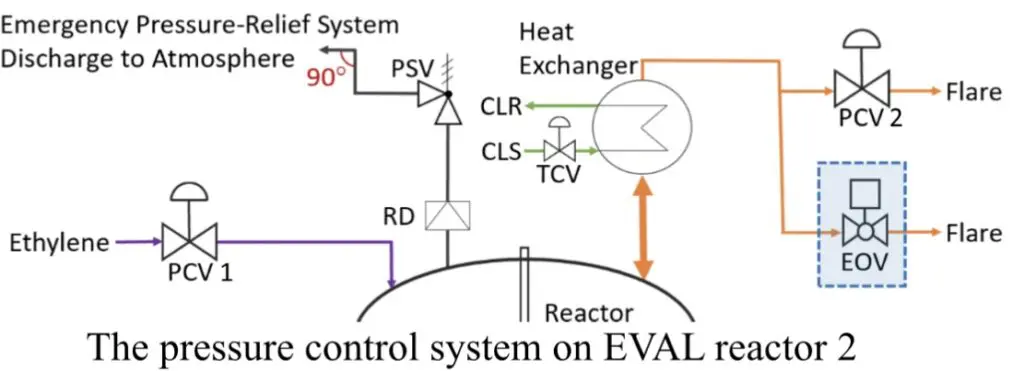

There were four reactors in the process. Three of these had a design pressure of 1150 psig (79 barg), however the reactor where the release occurred (EVAL reactor 2) had a design pressure of 740 psig (51 barg), otherwise it was identical to the others. The reactor had a water filled jacket and temperature could be increased by the injection of steam. The pressure in the reactor was controlled by the feedforward of ethylene into the reactor (PCV 1). Any excess pressure was relieved to the flare through PCV 2. A new cooling system was recently installed on the reactor, and this was the first time this system had been used. A safety interlock system on the reactor was also installed to discharge ethylene through an emergency blowdown valve (EOV) in the event of excessivepressure. The plant had a permit for emissions that had strict requirements on flaring.

During the start-up there was methanol liquid in the reactor and ethylene vapour was being added to increase the pressure. There were problems and the safety interlock was put into manual and used to discharge ethylene to the flare (EOV). The safety interlock was not switched back to automatic. The new cooling system was brought into service and led to an abnormally low temperature in the reactor resulting in condensation of the ethylene vapour. The cooling was stopped, and steam was injected into the jacket to increase the temperature. The ethylene vapourised and the pressure increased until a high-pressure alarm went off in the control room. The control room operator opened a pressure control valve (PCV) to discharge ethylene to the flare. The operator was concerned about exceeding environmental limitations on flaring and did not reduce the pressure to below the high-level alarm limit and pressure continued to climb. At this time there was a shift change. The new CCR operator noted that the pressure was high, however he did not recall that this reactor had a lower design pressure than the other three and was not concerned. The new operator opened the PCV to reduce the pressure however was distracted by other operations that he was also responsible for. He was also concerned on the amount of flaring and did not open the PCV sufficiently. The pressure reached a high-high level that should have activated the safety interlock; however, this was in manual and effectively disabled. The pressure continued to increase until the relief valve (PSV) opened discharging ethylene through a horizontal pipe into the area around the reactor. The ethylene ignited and 21 people who were working in the area were injured.

Forgetting to reinstate a safety system, failing to recall a design pressure, reacting to a new operating situation, being distracted by other tasks, and being concerned on exceeding environmental permits led to an overpressure situation. All these factors are understandable and could happen at your facility, so you need to help your people to ensure it doesn’t happen to you. The overpressure situation should not however have led to a danger for personnel. The ethylene should have been discharged to a safe location and there should not have been people in the area during a start-up. Why did the management at Kuraray America not ensure this and why did they not learn from similar incidents in the past? This will be covered in next weeks Reflektion.