The Weekly Reflektion 37/2023

Built-in obsolescence is one of the characteristics of our present day. Little is repaired and buying new is normally considered cheaper. Building schools with built-in obsolescence may lead to a disaster unless we understand the consequences.

If your house was built to last 30 years, would you live there worry-free after the 30 years were up?

The Weekly Reflektion from week 47/2019 discussed the Ponte Morandi bridge in Genoa which collapsed n 14th August 2018 killing 43 people crossing the bridge at the time. The bridge was built of pre-stressed concrete where cables were tensioned up before the concrete was poured around them. Water and salt ingress caused corrosion in the cables which, in turn, led to the collapse. In the UK at the present time, a there is controversy around the use of reinforced autoclaved aerated concrete (RAAC). There are concerns that the disadvantages of RAAC were ignored at the time when many buildings werebeing built.

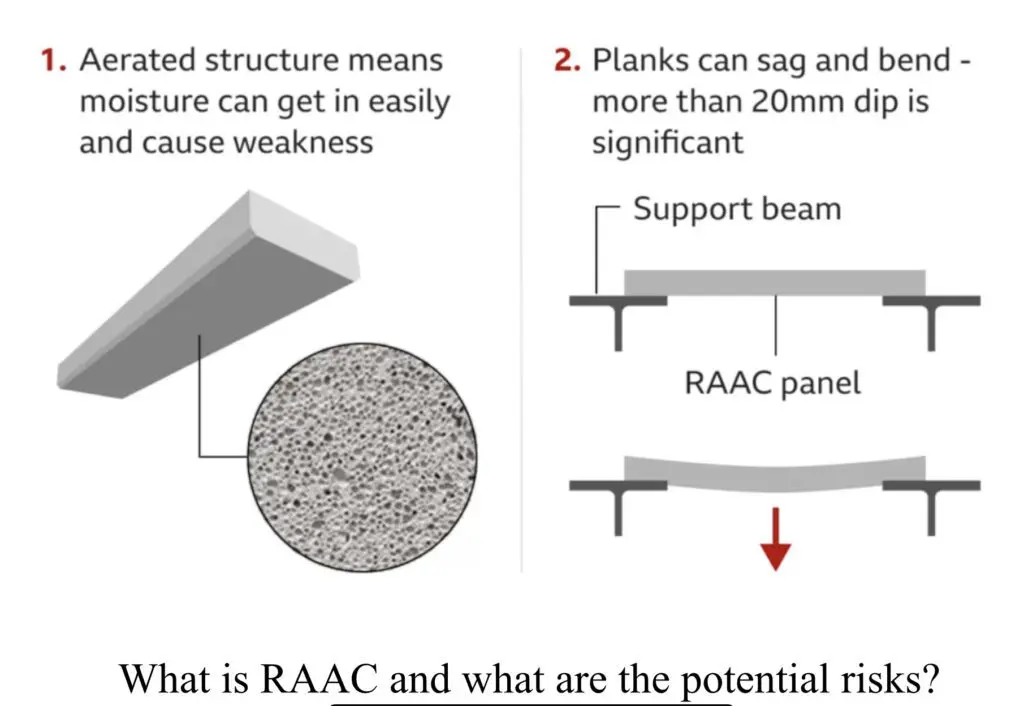

RAAC is a lightweight material that was used mostly in flat roofing, but also in floors and walls. It was used extensivelybetween the 1950s and 1990s as it was a cheaper alternative to standard concrete, being quicker to produce and easier to install. As can be seen in the figure, the concrete is aerated, or “bubbly”, like Aero chocolate (in the UK) or Stratos chocolate(in Norway). Its structural behaviour differs significantly from traditional reinforced concrete, as it is less durable and only has a lifespan of around 30 years.

RAAC is also susceptible to structural failure when exposed to moisture which can occur as the aerated structure allows water to enter the material. If that does happen, the rebar reinforcing the RAAC can decay, corrode, and weaken, similarly to the Ponte Morandi bridge. Due to these issues, which were known at the time of introduction, RAAC is often coated with another material, such as bitumen for extra protection on roofing panels. However, this material can also degrade.

The potential safety issues of ageing RAAC were first reported in the UK in the 1980s and 1990s, when roof collapses led to buildings being demolished. A recent civil service report recommended that many schools needed rebuilding annually due to the choice of building material. It is still unclear how many buildings have used RAAC, but the UK government estimate that hundreds of schools and university buildings could be affected. The Health and Safety Executive says RAAC is now beyond its lifespan and may “collapse with little or no notice“. Corrosion can occur without visual indication that the panel is in poor conditionand there is a risk of collapse without warning in panels over 20 years old. During the summer of 2023 a RAAC beam that had previously been considered low risk collapsed. The UKGovernment has announced a program to rebuild 500 schools over the next 10 years.

Kicking the can down the road usually has its disadvantages. Saving money in the building phase has resulted in a problem today. The knowledge was there at the start, the signals were seen underway, and the consequences were shocking when they were revealed in the recent report. As the controversy rages the UK government is being criticized for not doing enough to address the RAAC problem. We hope that the media will soon turn their focus to what can we learn and how can we avoid a new building controversy in the future. More importantly how can we learn to prevent a future building catastrophe.