The Weekly Reflektion 48/2021

New technology often gives us an opportunity to make improvements to the way we do things and how much time it takes to get It done. Sometimes however new technology may have unexpected consequences that can lead to catastrophic results.

When you introduce new technology or new ways of working, are you good at managing the changes?

The Swiss cheese model of accident causation was originally proposed by James Reason and is often used to illustrate barriers in place to prevent accidents and/or reduce the resulting consequences. The model includes both active and latent failures sometimes referred to as respectively unsafe acts, and conditions that are unwittingly included in the designand are just awaiting the right circumstances to contribute to the accident. This Reflektion looks at the introduction of a latent failure.

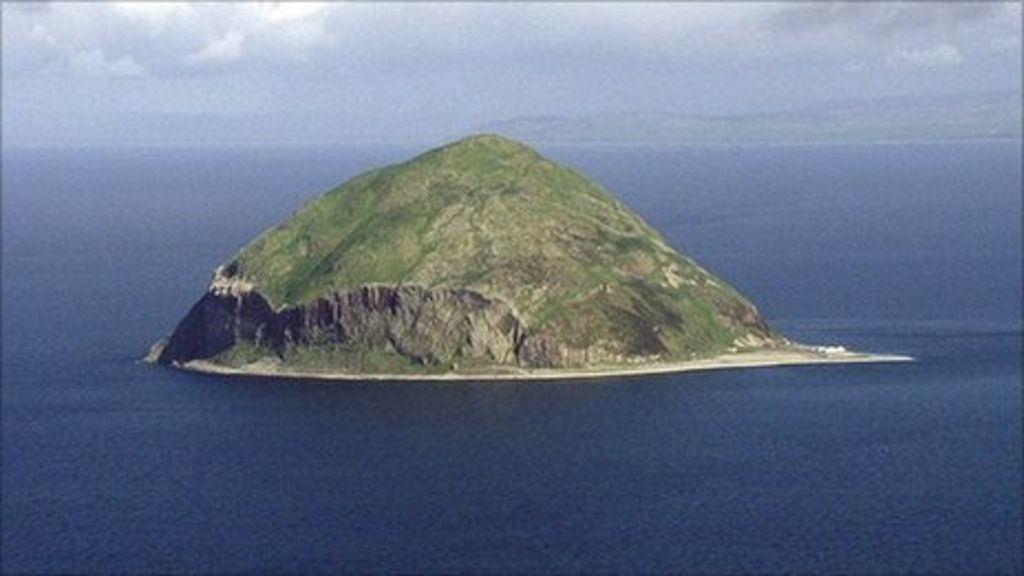

The island of Ailsa Craig in the Firth of Clyde in South-West Scotland is an igneous intrusion, the remains of an ancient volcano. The granite has a micro-composition and crystalline texture that makes it particularly hard and resistant to impact. Granite from the Ailsa Craig is a favoured material for the manufacture of curling stones. Next time you are curling you will likely be sliding a piece of Ailsa Craig granite across the ice.

Granite from Ailsa Craig is quarried in batches of up to 4000 tonnes and the granite for curling stones is carefully selected for both structure and colour. The curling stones themselves are made locally using machinery that is over 80 years old. A few years ago, the manufacturer purchased a new diamond cutting tool that would reduce the time and cost of producing a curling stone. A few months after the stones cut with the diamond machinery were delivered complaints were received that some of the stones had started to crack. This was unusual as cracking was rare on the stones cut on the conventional machinery. The manufacturer investigated the problem and discovered an unexpected consequence of the introduction of the new technology.

When using the conventional machining tools, the workers had to study each granite piece carefully, select only the best pieces, and plan the machining with reference to the natural lines and planes in the structure. Failure to do this often resulted in problems with cracking during the machiningprocess. The conventional machines generated a significant amount of vibration that could damage the granite. This process eliminated material with inherent cracks and micro cracks that would make the finished stone susceptible to cracking when they collided with other stones during curling. Introduction of the diamond cutters meant that poorer quality material could be used to produce a finished curling stone.

Introduction of new technology and new ways of working can give significant advantages in an operation, however, can introduce problems that can give unexpected and even catastrophic results. The change may introduce a latent failure that may not be immediately apparent but over time will be the cause of an accident. Reflekt has emphasized the challenges of managing change in several Reflektions and we will continually come back to this issue as we see that it a major factor in many Major Accidents. Do you have a good process for managing changes, and for encouraging people to use their imaginations to identify potential latent failures?