The Weekly Reflektion 17/2023

Quality and quality assurance is vital to the safe and successful delivery of any project. One of the key elements in quality assurance is the application of appropriate standards. The assessment of what standards apply, and their correct application is in turn dependent on people with the necessary knowledge and experience.

How do you ensure that standards are applied properly in your project?

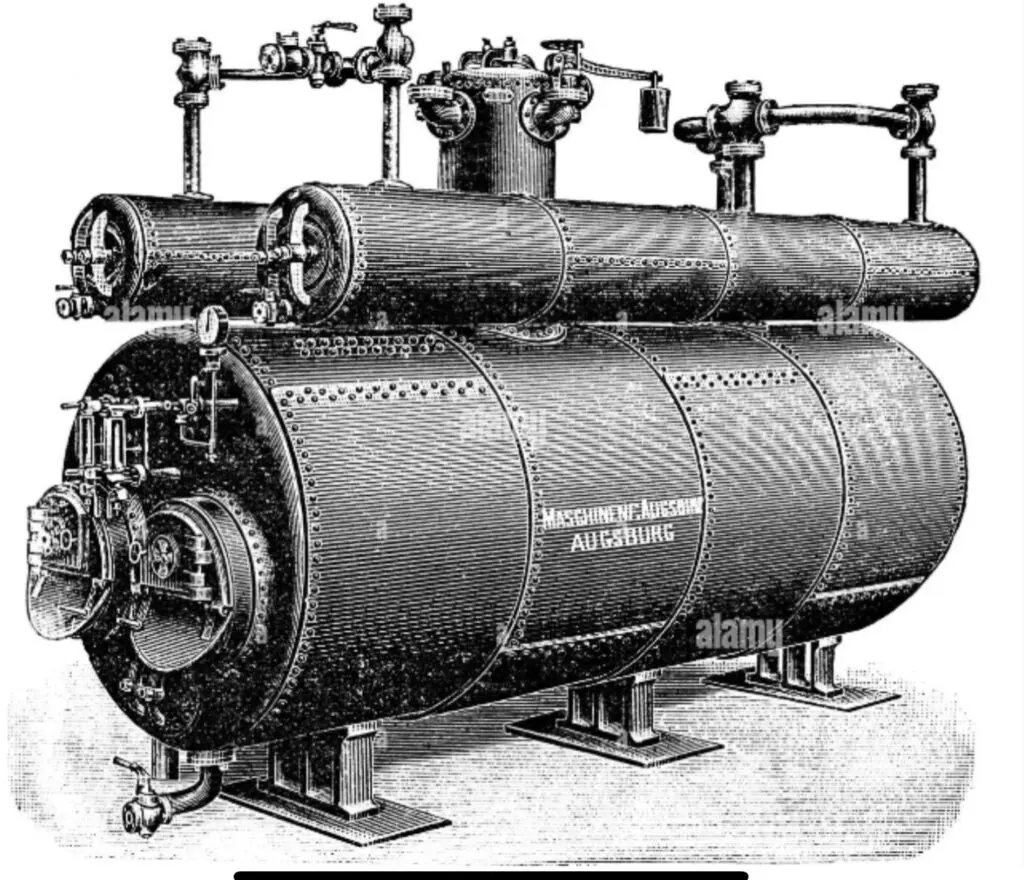

In the March 1881 edition of Scientific America there was an article on steam boilers and the regular occurrence of steam boiler explosions.

The records kept by the Hartford Steam Boiler Inspection and Insurance Company show that 170 steam boilers exploded in the United States last year (1880), killing 259 persons and injuring 555.

From 1905 to 1911 in the US there were 1700 steam boiler explosions killing 1300 people ca. 300 per year. From 1915 the annual boiler explosion rate was 20 per year. What was the reason for this dramatic change?

In the period 1881 to 1915 there was a drive to improve boiler safety in the USA that was unfortunately resisted by the industry owners who were skeptical to any changes that may increase costs for building new steam boilers and operating existing ones. The American Society of Mechanical Engineers (ASME) was established in 1880. ASME is a not-for-profit professional organization that enables collaboration, knowledge sharing and skill development across all engineering disciplines, while promoting the vital role of the engineer in society. In 1914 the ASME Boiler Design and Construction Code was developed. It was the first complete standard of its kind in the world and is still being used in its updated form today. The standard included compulsory installation of pressure relief valves, guidance on the pressure the valve should open and calculation of the capacity of the installed relief valve(s). There was also guidance on inspection of the boiler and the relief valves themselves. Many states made application of the ASME standard compulsory and insurance companies required compliance with the ASME standard as a pre-condition for any insurance policy.

The principles in the ASME standards are now applied to the petroleum industry and typical standards for overpressure protection of process facilities used today are API 14C, NORSOK S-001, API 520/521, ISO 13702. These standards give guidance on number of levels of protection (typically two), design pressure, relief capacity, response time for the relief devices and disposal systems (typically a remote flare for hydrocarbon systems). The standards require companies to investigate potential overpressure scenarios and typically the design basis is described an ‘the worst credible scenario’.

On 23rd March 2005 an overpressure situation occurred at the Texas City refinery in US. The pressure relief valves operated as designed however these discharged into a blowdown vent located in the refinery. The discharged hydrocarbon overflowed the vent into the atmosphere and the vapour cloud was ignited by a nearby diesel truck. 15 people died and 200 were injured. The relevant overpressure protection standard at the time required a remote flare as the disposal system for any pressure relief. Amoco the original refinery operator and BP the operator at the time were aware of the relevant standard and had assessed a modification. The cost however did not fit the 25% reduction in operating costs that BP Management had set as an objective for their refineries.

Reflekt will organise our first live breakfast seminar post COVID on Wednesday 3rd May at Ipark in Ullandhaug, Stavanger. Follow our website for more details. https://reflekt.as/events/